Electricity Safety Audit

Electrical Safety Audit is about examining the safety & security of electrical installations of any industrial unit or organization. Electrical Safety Audit is performed by conducting enquiry, inspection, testing and verification of any entity installed with electrical equipment and appliances. Electrical Safety Audits are conducted by experienced professionals who assist clients in reducing risk and help to ensure compliance with applicable Safety Standards and Regulations.

We follow a systematic approach for evaluating potential electrical hazards and produce reports recommending actions for improvement in Electrical Safety Audit. Electrical Safety Audits include the factory assessment of electrical installations in various industries such as Electrical, Construction at various Cities across India.

Approach & Methodology

The Electrical Safety Audit includes the review of documentation with respect to the scope covered in audit, an on-site visit, and data collection, their review and analysis. This will also require the cross-check and verification of information and data which may include industry norms and peer data. Following is the methodology which we follow at SABS Group for conducting an Electrical Safety Audit in detail:

- A Pre-Audit Meeting (opening meeting).

- On-site visit and inspection

- Discussion with members of the house.

- Discussion with members of the house.

- Submission of final electrical safety audit (ESA) report

Scope of Electrical Safety Audit

Electrical Safety Audit reviews the degree of safety of the overall electrical system in the premises, providing recommendations and measures to be taken to minimize or eliminate the risk of electrical hazards. The following is the scope in detail:

- Review of the electrical hazards identification and risk assessment.

- Water system analysis

- Water system analysis

- Review of the earthing and lightning protection system implemented in plant to ensure the equipment and human safety.

- To check the hotspot in the electrical installation and equipment by using thermal imager.

- To check earth resistance of earth pits and sockets on sampling basis.

- Review of EPM (Electrical Preventive Maintenance) programme in the facility.

- Review of the electrical documents like register of electrical installation, single line diagrams, test records (Transformer oil test, Insulation Resistance test and Earth Resistance tests) and data sheets of critical electrical installations.

- Review of the availability & reliability of emergency systems such as DG set, UPS, battery etc. Physical verification of warning signage & labeling on all electrical distribution panels, transformer and switch-gear.

BENEFITS OF ELECTRICAL SAFETY AUDIT

- Identification of Electrical hazards helps to minimize the risk of accidents like fire due to short-circuiting,

- Identification of areas of risk or vulnerability in the existing electrical systems and installations.

- Improves employee morale by ensuring safer place to work.

- Premature failures are effectively minimized.

- Unexpected outages can be minimized ensuring continues power supply to the end user.

- Assisting in the management of Electrical risk

- Non-compliance with the legislation and best practices.

Electrical Testing

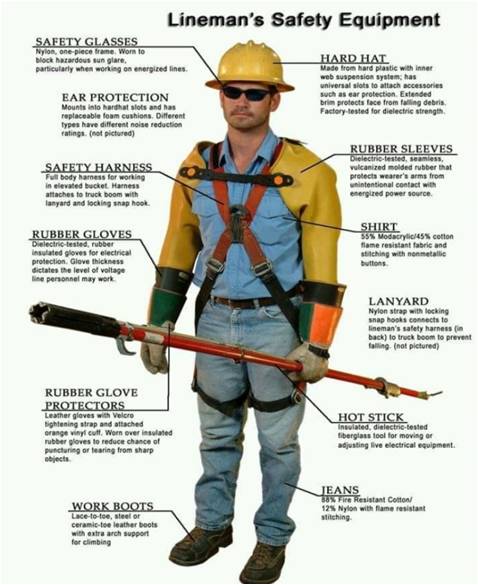

An electrical testing service plays a crucial role in ensuring the safety, reliability, and compliance of electrical systems in various settings. These services involve the examination and assessment of electrical components, systems, and installations to identify potential issues, ensure conformity with standards, and prevent electrical failures. Skilled technicians use specialized equipment to conduct a range of tests, including insulation resistance, continuity, circuit breaker functionality, and power quality assessments. Electrical testing is particularly vital in industries, commercial buildings, and residential spaces to mitigate the risk of electrical hazards, enhance energy efficiency, and maintain optimal performance. Additionally, it is often a requirement for regulatory compliance and insurance purposes. A comprehensive electrical testing service not only helps identify existing problems but also serves as a proactive measure to prevent future electrical malfunctions, ensuring the safety of occupants and the longevity of electrical systems.

Testing (Scope of Work):

- Main Panel & DB

- Insulation Resistance test

- Bus bar integrity test / Torque test

- Earth resistance test

- Current injection test for MCCB's

- Functional Checkup

- Thermography test of breakers and cables terminations

- Cable

- Insulation Resistance test

- Termination integrity test

- Distribution Board

- RCCB Functional Check up

- Light Fitting, Wiring

- Circuit Check

- Lux level test

- UPS Socket

- Circuit Check

- Voltage measurement

- Earth resistance test

- Earth loop impedance test

- Polarity Check

- RAW Power Socket

- Circuit Check

- Voltage measurement

- Polarity Check

- Earth Pit resistance test

- Relay Testing_

- Transformer_IR_Testing

- Insulation_Test_Motor

- IR_TESTING_CABLES

- TAN_DELTA_TESTING_TRANSFORMER

- TRANSFORMER_OIL_TESTING_FILTERATION YEARLY

- THIRD_HARMONICS_LA

- ACB_TESTING_YEARLY

- Arc Flash (AF) study: