Thermography Service

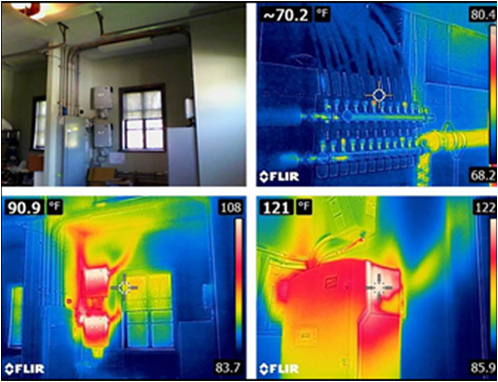

Thermography is a technique of analysing the thermal characteristics of an object from its infrared image, captured through non contact thermal imaging device. Infrared thermography allows us to see heat energy radiated by objects (Both cold and hot bodies emit this type of energy).

Applications:

- For Transformers: Infrared imaging of the transformer can often detect oil level and radiator convection cooling problems.

- For the Batteries: can detect the individual faulty cells by measuring the temperature without contact,

- At The Electic Panels: Infrared thermography is used to perform Preventive Maintenance inspections-

We recommend regular thermography surveys of the following types of equipment:

HEATING APPLICATION :

- Distribution boards

- Busbar systems

- Control panels

- High voltage and medium voltage systems

- Power line connections and insulators

- Switchgear

- Electronic components

- UPS and battery systems

- PLC connections

- Motor control centers

- Transformer

- DG Set

- Boiler & Furnaces

COOLING APPLICATION :

- HVAC application

LEAKAGE OF WATER &COMPRESSED AIR :

- Compressed air piping lines

- Plumbing pipes

BENEFITS OF THERMOGRAPHY ANALYSIS

- Determines if the components and system have been properly installed and are not damaged

- Reduces downtime

- Increases safety

- Improves insurability

- Reduces liability exposure of the designers and installers

- Improves system performance

- Determines whether components and systems operate properly and meet the design intent

- Determines if components and systems are in compliance with the project specifications and design

- Reduces construction schedule delays

- Identify water leakage in pipe lines

- Identify compressed air leakage in pipe lines